Language:

Created By : Dhani Hendyansyah

Copyright @2014, PT. Nusantara Parkerizing - Metal Surface Treatment Technology, Rolling-Oil, Nox-Rust in Indonesia

Product Profile

|

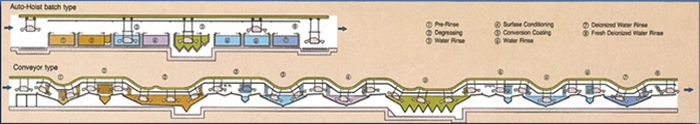

There are three methods: Dip Process, Spray Process and Spray/Dip process. in treating car bodies, full Dip is adopted in many cases aiming at rusr prevention of inner parts |

Metal Surface Treatment ChemicalsAs the pretreatment for painting degreasing/rinsing and rust prevention conversion coating processes of steel sheet surface of the car body. this pretreatment is so important that it enhances rust preventive power as well as paint adhesion of the object under treatment and determines the last finishing. |

|

|

|

|

Rolling Oil |

We provide Rolling-Oil as a supporting material at the Cold Rolling Mills factory to reduce metal thickness. The Rolling-Oil is a medium that helps in pressing the metal to the required thickness. Rolling-Oil also cleans the Coil Strips surface after rolling and prevents the coil strips against rust for a limited time. Our Rolling-Oil is widely used by many mills around the world and it considered the best. Our Rolling-Oil has a good waste disposability. |

Nox-Rust / Rust Preventive oil |

We also provide rust preventive oil with the brand name Nox-Rust. Nox-Rust helps in protecting a coil strip after Cold Rolling Mills for a longer period. We provide variety types of Nox-Rust for different purpose of latter treatment. Nox-Rust is also widely used by many industries due to its compatibiltiy for their next processing. |

Other Chemicals |

We also provide many kinds of chemicals for after mills processing such as "Wet Temper Solution", "Degreasing & Phosphating Chemicals", also other cleaning chemicals for increasing the quality of the coil strips. All of our product has passed tight quality checking before delivered to our customers. |